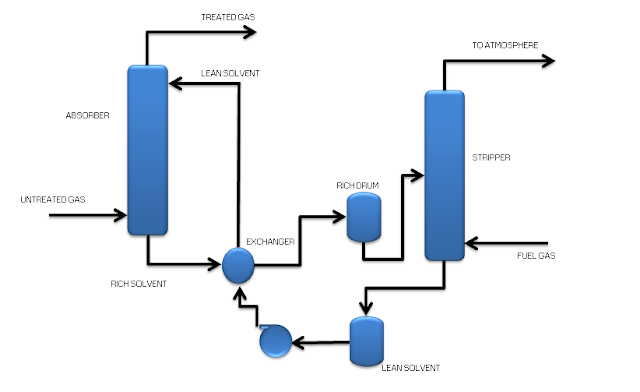

Generally you will observe these two columns together.

Purpose of absorbtion column is to react with one of the

components in a mixture of fluid which will enter from the bottom of the column

with an absorbent from top of the column so these two fluids come in contact counter

currently.

In general abosrbtion favors low temperature , high

pressure conditions and the streams which are coming in are to be maintained at same temperature.

OK but why we have to maintain same temperature?

Hint: Henrys Louis lechatilier principle.

If you observe the solubility curve the solubility increases

with increasing in pressure which was drawn at "constant Temperature"

So absorbtion favors high pressure is very important term but

we should not forget Constant Temperature term which is much more important.

To maintain Constant temperature in a process, temperature controllers

(PID) are used. Some times on both the streams or keeping one stream (absorbate)

as it is and mounting temperature controller on absorbent stream.

Now the solvent after absorbing will be coming out as a RICH SOLVENT which has to be regenerated using a stripping column(See Below Section).

Examples of absorbtion column:

GAS DEHYDRATION COLUMN where gas will be dehydrated using

TEG.

AMINE ABSORBTION COLUMN where sour gas is treated with AMINE.

Stripping Column:

Purpose of stripping column: Purpose of stripping column is to regenerate Lean Solvent from Rich solvent and using fuel gas a stripping fluid.

Mostly stripping columns is used in Regeneration units.

Stripping favors high temperature low/normal pressure operations reverse of absorbtion.

So generally Rich Solvent will be preheated before sending to a stripper(Or Reboiler type column is used).

Before sending the regenerated solvent to a storage section it will be cooled again.

Mostly stripping columns is used in Regeneration units.

Stripping favors high temperature low/normal pressure operations reverse of absorbtion.

So generally Rich Solvent will be preheated before sending to a stripper(Or Reboiler type column is used).

Before sending the regenerated solvent to a storage section it will be cooled again.

Examples of stripping column:

AMINE REGENERATION COLUMN.

TEG REGENERATION COLUMN.Modeling point of view:

From modelling point of view(OTS Purpose).

PFD(Process flow Diagram),P&ID(Piping and Instrumentation Diagram),HMB(Heat and Mass Balance)

Column GA drawings : To know the nozzle positions, column dimensions,liquid level maintenance and elevations etc.

Corresponding equipment's data sheets:

For exchangers: HTRI Datasheets helpful to verify the duties.

For Pumps: Pump curves helpful to verify the head and power.

Vessel: Drawings and dimensions.

Cause and effect diagrams: Which uses the transmitter information and effect is on SDV(Shut down valves) useful for safety point of view.

Alarm list: Transmitters high,low,high high ,low low limit information.

Isometrics

etc.

No comments:

Post a Comment